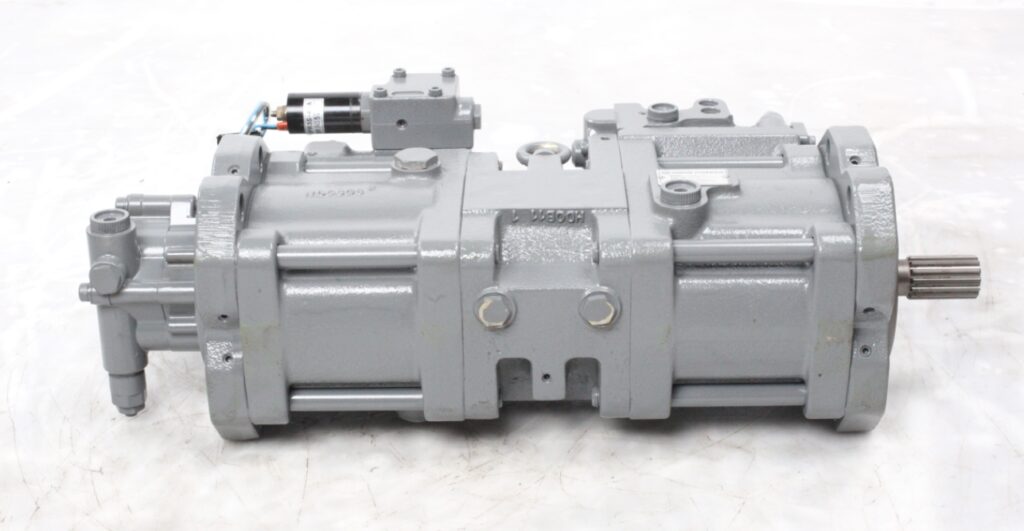

Excavator Hydraulic Pump Maintenance Guide

- Product knowledge

- Mar 20, 2024

The hydraulic pump of an excavator plays a pivotal role in its operation, providing the power and control necessary for efficient performance.In order to extend the life of the excavator.

We should regularly check and maintain the Excavator hydraulic pump.

Four aspects in maintaining hydraulic pumps:

Regular inspection and maintenance:

Regularly inspect the hydraulic pump and its surrounding connecting parts and seals to ensure there are no leaks or wear.

Check the operating pressure and flow rate of the hydraulic pump to ensure it is within the normal range.

Regularly check the cooling system of the hydraulic pump to keep the temperature within the appropriate range.

Keep your hydraulic system clean:

Clean the external surfaces of the hydraulic system regularly to prevent dust and debris from entering the system and causing damage.

Clean the hydraulic tank and filter regularly to avoid accumulation of dirt and impurities that may affect oil quality.

Use high-quality hydraulic oil and filters:

Choose high-quality hydraulic oil that meets the equipment specifications and ensure it has good viscosity and antioxidant properties.

Replace hydraulic oil and filters regularly to avoid the impact of oil aging and contamination on the system.

Identify and resolve problems promptly:

Conduct regular fault diagnosis and analysis of hydraulic pumps and hydraulic systems to discover and solve potential problems in a timely manner.

According to the working conditions and usage environment of the equipment, take corresponding maintenance and upkeep measures to prevent problems from occurring.

By following these basic principles, you can effectively protect and maintain hydraulic pumps, extend their life time, and ensure the safe and reliable operation of equipment such as excavators.

The Three aspects should be avoided when operating a hydraulic pump

Avoid overloading and overheating operation:

When the excavator is working, avoid overload operation to avoid excessive pressure and load on the hydraulic pump and hydraulic system.

Check the hydraulic oil temperature regularly to ensure it is operating within the appropriate range. Excessively high hydraulic oil temperature will reduce the oil lubrication performance and accelerate the wear and aging of the hydraulic system.

Warm-up and hydraulic system inspection before operation:

Before cold start, perform appropriate preheating to ensure that the hydraulic oil and hydraulic pump are within the operating temperature range.

Before operation, conduct a comprehensive inspection of the hydraulic system, including checking the hydraulic oil level, hydraulic pipelines, seals, etc., to ensure that there are no leaks or damage.

Prevent hydraulic system contamination and water intrusion:

Change hydraulic oil and filters regularly to prevent contamination and impurities from entering the hydraulic system. Contaminated hydraulic oil will accelerate the wear of hydraulic pumps and hydraulic systems.

During operation and storage, keep the hydraulic system in a clean and dry environment to prevent moisture and impurities from entering the system and causing corrosion and damage.

It can effectively protect and maintain hydraulic pumps and Hydraulic Pump Assy, reduce the risk of failure and damage, extend the service life of equipment, and ensure the safe operation and efficient operation of heavy equipment such as excavators.

These are common maintenance methods for hydraulic pumps. If you need hydraulic pumps and hydraulic pump parts, you can also contact us. We have a variety of hydraulic excavator pump and hydraulic pump spare parts, and we have a professional team to help you. We will provide you with the latest product catalog and respond to you within 2 hours.

The blog is for reference. For more accurate information, please consult professional experts and technicians.